Cutting-edge torsional cables

usable with any type of furler

Armare Ropes Torsional Cables are designed, built and tested in our laborstory, with cutting-edge techniques and machinery that allow a precise evaluation of the torsional static and cyclic resistance, simulating the behaviour of the cables on board. The technological development has enabled the design and realization of a wide range of structural torsional cables, which permits the application of this technology also for the winding of luffed headsails like code zero sails, drifter, solent and staysails. Torsional cables have now become essential on any cruising or racing boat, offering incomparable performance, higher than any other textile cable/rope.

Fibers and terminals

Standard cables are made of the same fibers used for single cables: PBO-Zylon®, or Dyneema® SK99, Dyneema® DM20, Kevlar® 49. The cables can be supplied either with a couple of terminals AT or with one terminal AT and one other specific terminal for lashings. When using a specific terminal for lashings the cable must be shorter than the sail. Then it is connected to the drum fork by a structural lashing made of Dyneema® rope of the appropriated diameter and length.

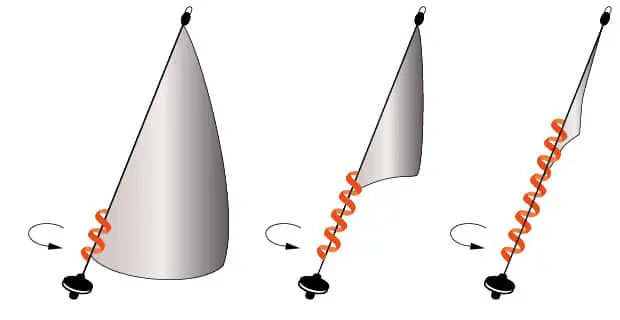

Principle of the traditional winding, so called, because the torque transmission happens from the bottom upwards. The sail is secured with a lashing on both end of the cable; the torsional force is applied to the drum and the textile cable transmits the torque along the cable until the opposit end (at the top) and the sail begins to wrap from the bottom to the top.

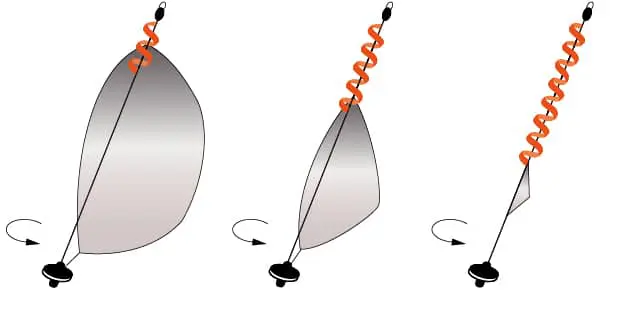

In this case, the tack of the sail is fixed to the drum through one free tack swivel: the torsional force applied to the drum is transmitted almost instantly to the swivel at the top and it causes the winding of the sail from the top to the bottom. When the winding is completed, the halyard can be released and the sail can be easily traversed and stowed.

Case studies

All the cables can be built on specific requirements of designers, based on parameters of breaking load (ton) or stiffness (ea). They can be used with all modern and sophisticated furling systems and the terminals are pre-drilled to the exact size, In order to hold the pins of the furler.

Composite Cables

& Standing Rigging

Standing rigging systems in PBO-Zylon®, code cables, no-torsion cables, strops and steel fittings. Click the link below to download the PDF catalogue.