Special Treatments

Four special treatments, which may be applied to technical fibers or single braids, to improving their performance and duration over time.

Impregnation treatments

In addition to the special treatments, the fibers can be treated with the latest

generation impregnating agents that increase the expected performance.

HPS Treatment

HPS Treatment (Heat Prestretch Setting) regulates the tensioning of the fibers that make up the rope and sets them in an optimal way, bringing them to a high temperature and subjecting them constant load for a given time.

Rope without treatment

Single braid Dyneema® without HPS treatment: the braid is soft and “airy”.

Rope with HPS treatment

The braid after the HPS treatment: the fibers are oriented and the rope is more rigid and compact.

HPS: main advantages

- Specific modulus increase

- Decreased constructive elongation

- Breaking load increase

- Greater compactness

- Decrease in diameter

- Decreased flexibility

Why choose ropes with HPS treatment

The rope with with HPS treatment has a very high specific modulus, without construction elongation and a higher breaking load, if compared with non-prestretched ones. Furthermore, the rope is much more compact, less

flexible and therefore thinner than a rope with the same non-prestretched core.

On performing boats is to be preferred to use prestretched ropes on halyards; in this application, the slightly higher stiffness of the ropes will not be a problem, as they are used much less than other lines. On high-level racing boats, almost all the running rigging is made with prestretched ropes; among them the fiber used and the composition of the cover can vary.

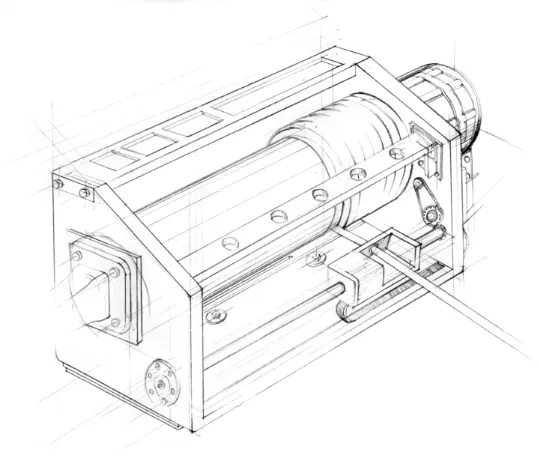

Captive Winch Treatment

Treatment applied on the ropes intended to be used on Captive Winches of large Super Yachts. The treated ropes preserve high breaking loads and low elongation thanks to the use of high modulus fibres.

Rope with Captive treatment

The rope with Captive treatment is linear and compact; core and cover perfectly fit together.

Rope without Captive treatment

The rope without treatment could show a progressive “slack” that accumulates gradually and may cause damage to the cover.

PU Coating treatment

The Dyneema® braid impregnated with the Polyurethane Coating gains advantages in terms of compactness, reduction of compression under load and, therefore, roundness.

This coating becomes even more important when the ropes have to be worked and/ or when the cover has to be removed as the polyurethane keeps the Dyneema® fiber linked, this increases the quality of the product in terms of durability and abrasion resistance.

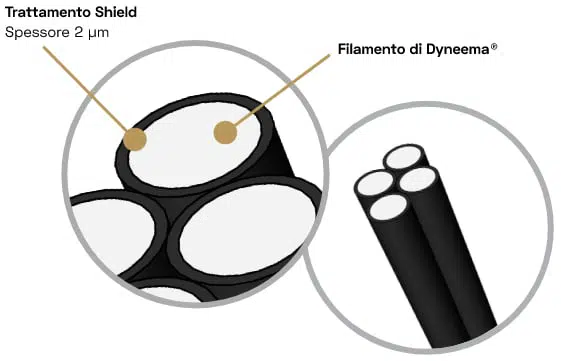

Shield Process

Armare Ropes introduces the “Shield process”, a latest generation treatment which represents the highest protection against wear.

How the Shield is applied

The basic fiber is impregnated with a coating that dyes it only externally; when slicing it, the inner side is white while the external surface is pigmented.

The Dyneema® filaments are spinning in a raw/natural colour and in a second phase they are coated with a special coating blend PU based.

“Shield” is the name given to a specific unifilar impregnation treatment applied to the Dyneema® fiber by using a very special protective coating that creates a kind of “Shield” all around the pure fiber.

Apart from reducing the exposure of the fibers to UV rays thanks to its opaque pigments, it also lowers remarkably the friction between the fibers themselves, usually caused by the load applied to the ropes and/or by the movement and bending around the pulleys.

It has been proved that “Shields” significantly increase the fatigue and flexion cycles of the ropes realized in Dyneema® and it is used extensively for the construction of the Endurance line ropes.

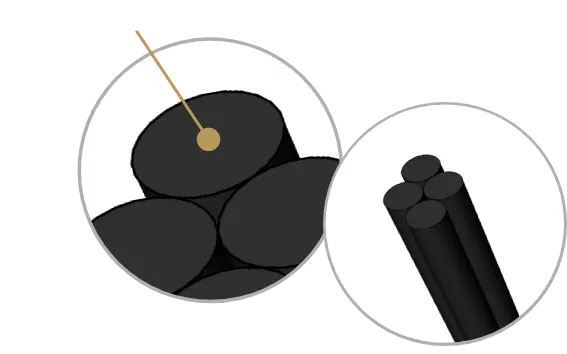

Pure Black Dyneema

Dope-Dyed process: the best solution to protect the colour against UV rays

Thanks to the new entry of Dyneema® BK (BLACK), nowadays we are able to produce a black rope totally made with Dyneema® without degradation of colour. This process allows to obtain a stable and long lasting coloring of the fibre without any compromise in terms of durability and resistance to UV rays.

Dope-Dyed process

The fiber is colored in and out i.e. when slicing it you will see that the color is uniformly present on the whole surface of the sectioned filament.

The Dyneema® filaments are fully impregnated with pigment during the spinning (Dope-Dyed) and the result is a solid colour that is the same in and outside the base filament.

The “DOPE-DYED’’ coloring allows to obtain a stable and durable black colour with a slight loss of technical performance in terms of breaking load. This treatment is used extensively for the construction of our Endurance line ropes.